Isotech offers a full range of Fiber, C02, UV, Green, MOPA, Nanosecond, Picosecond and Femtosecond laser systems for marking, cutting and welding of many substrates. Isotech offers both standard systems as well as fully automated or custom systems depending on your specific requirements. Integrated, automated solutions with conveyors, palletized pick and place, rotary dial tables, hoppers, and...

For over 50 years, we have been continuously improving upon and developing new industrial laser systems, with a focus towards the processes of cutting; welding; marking and engraving; and micromachining, providing unmatched total solutions to our global customers. We are a technology driven company, offering laser system customization and providing a “One Stop” laser technology solution and...

Hai Tech specializes in state-of-the-art laser technology, offering both new and refurbished industrial lasers and marking lasers for automotive, tooling and electronic applications. We have over 20 years of experience in laser system design so we can serve you better! For more information, contact a Hai Tech representative today!

Laser Marking Technologies LLC engineers laser systems for the medical, manufacturing, and automotive industries. We provide you cutting-edge technology at competitive prices. We are making innovative strides with fiber lasers, 3D printing tech, and automation capabilities that optimize manufacturing processes. Visit our site today to learn more about what our laser expertise can do for you.

TYKMA Electrox specializes in the design and manufacture of permanent industrial marking laser systems. Product line includes laser marking systems, electrolytic etch marking systems, needle marking systems and customized workstations. We are at the forefront of new product designs and problem solving.

If your business has a challenging component to mark on, our team at Automark will help you solve the problem. We supply laser and marking systems for a multitude of industries. Our team of engineers is ready and willing to tackle any of your challenging assignments. If you have any questions feel free to give us a call and a representative will speak with you today!

More Diode Laser Manufacturers

CD players, DVD players and all other disc reading equipment usually use diodes for scanning, and many printers and scanners use diode lasers both for scanning and printing. High-power diode lasers can be used in industrial operations like cutting, welding, cladding, heat-treating and many other processes. Recent advances in diode technology have propelled diode lasers into the healthcare industry.

Diode lasers are often well suited to minor procedures requiring small incisions because they are sterile and precise and can reach areas that would be difficult to reach with blades; this makes them especially helpful in dental procedures. The use of a diode laser and the color of the light it generates are determined by the wavelength of that light. The extreme highs and lows of the spectrum are usually reserved for experimental or very technical processes; very low wavelength diode lasers are used for fluorescence microscopy, and very high wavelength diode lasers are used for gas sensing. The in-between frequencies are reserved for CD players, laser pointers and other more common applications.

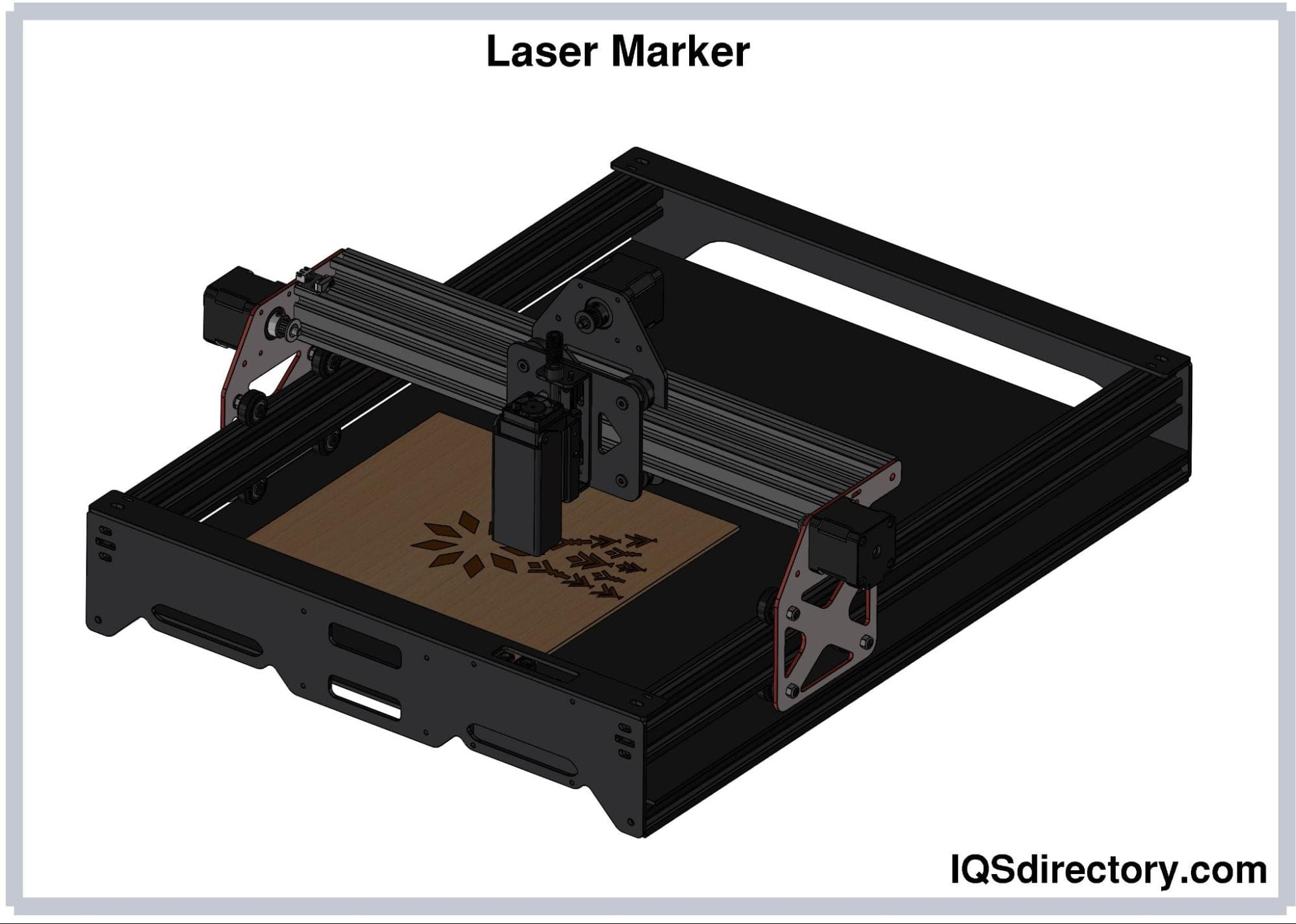

Laser is an acronym for Light Amplification by Stimulated Emission of Radiation. All laser equipment amplifies light and focuses it with a series of lenses. Diode lasers are no different. The main difference between diode lasers and other laser system varieties is a diode laser's means of light generation and amplification; this, along with wavelength measurement, is how all lasers distinguish themselves from each other. Every laser system requires a light amplification enclosure within which must be present a gain medium and electricity source.

Gain media are the substances that generate light and amplification; they can be solid, liquid or gaseous. In the case of diode lasers, gain media are usually combinations of chips made of semiconductive materials like gallium arsenide. When the diode gain medium is charged with electricity, electrons become excited and move between energy levels. This movement causes the emission of photons, the radiation of which is also known as light.

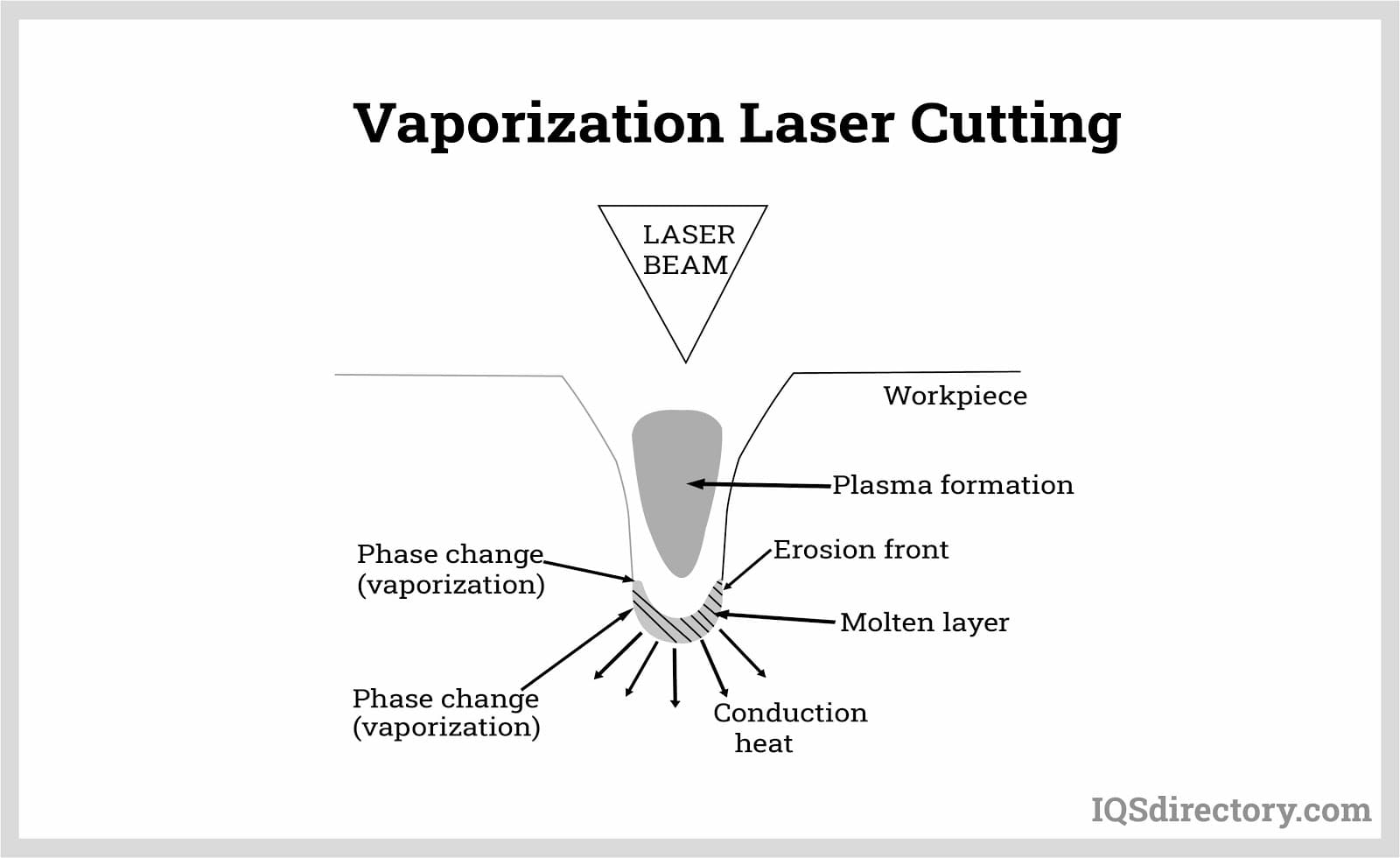

This light is directed by strategically placed mirrors within the amplification enclosure and then focused by at least one lens. The focal point of the beam, depending on the strength of the light implication and its wavelength, is the locus of heat caused by the light. It would be at the focal point where the light is most visible in the case of laser pointers; it would also be where metals or other materials would be positioned if they were to be welded, cut or otherwise treated by the beam.

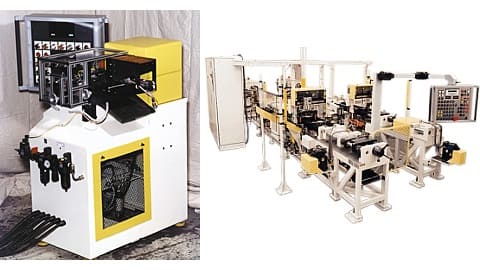

Automation Equipment

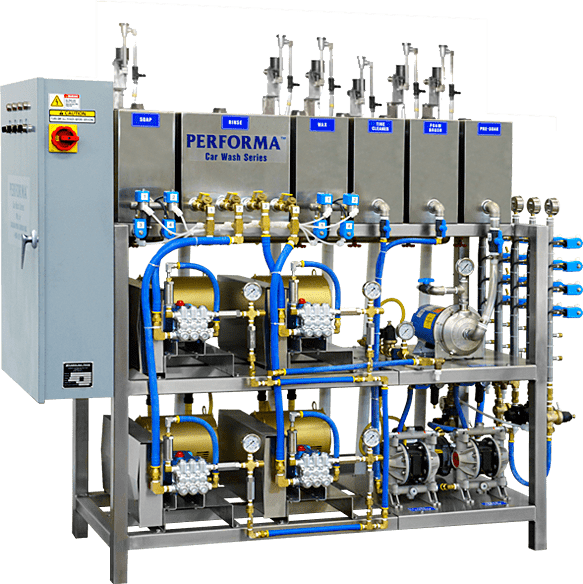

Automation Equipment Car Wash Equipment

Car Wash Equipment Centrifuges

Centrifuges Hydraulic Presses

Hydraulic Presses Lasers

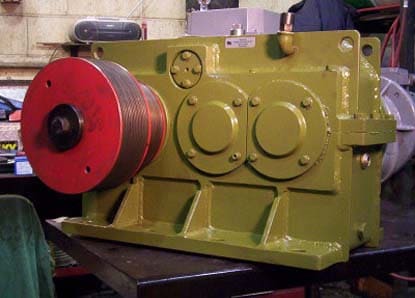

Lasers Machinery Rebuilders

Machinery Rebuilders Paint Finishing Equipment

Paint Finishing Equipment Tube Forming Machines

Tube Forming Machines Castings & Forgings

Castings & Forgings Bulk Material Handling

Bulk Material Handling Electrical & Electronic Components

Electrical & Electronic Components Flow Instrumentation

Flow Instrumentation Hardware

Hardware Material Handling Equipment

Material Handling Equipment Metal Cutting Services

Metal Cutting Services Metal Forming Services

Metal Forming Services Metal Suppliers

Metal Suppliers Motion Control Products

Motion Control Products Plant & Facility Equipment

Plant & Facility Equipment Plant & Facility Supplies

Plant & Facility Supplies Plastic Molding Processes

Plastic Molding Processes Pumps & Valves

Pumps & Valves Recycling Equipment

Recycling Equipment Rubber Products & Services

Rubber Products & Services