Isotech offers a full range of Fiber, C02, UV, Green, MOPA, Nanosecond, Picosecond and Femtosecond laser systems for marking, cutting and welding of many substrates. Isotech offers both standard systems as well as fully automated or custom systems depending on your specific requirements. Integrated, automated solutions with conveyors, palletized pick and place, rotary dial tables, hoppers, and...

For over 50 years, we have been continuously improving upon and developing new industrial laser systems, with a focus towards the processes of cutting; welding; marking and engraving; and micromachining, providing unmatched total solutions to our global customers. We are a technology driven company, offering laser system customization and providing a “One Stop” laser technology solution and...

Hai Tech specializes in state-of-the-art laser technology, offering both new and refurbished industrial lasers and marking lasers for automotive, tooling and electronic applications. We have over 20 years of experience in laser system design so we can serve you better! For more information, contact a Hai Tech representative today!

Laser Marking Technologies LLC engineers laser systems for the medical, manufacturing, and automotive industries. We provide you cutting-edge technology at competitive prices. We are making innovative strides with fiber lasers, 3D printing tech, and automation capabilities that optimize manufacturing processes. Visit our site today to learn more about what our laser expertise can do for you.

TYKMA Electrox specializes in the design and manufacture of permanent industrial marking laser systems. Product line includes laser marking systems, electrolytic etch marking systems, needle marking systems and customized workstations. We are at the forefront of new product designs and problem solving.

If your business has a challenging component to mark on, our team at Automark will help you solve the problem. We supply laser and marking systems for a multitude of industries. Our team of engineers is ready and willing to tackle any of your challenging assignments. If you have any questions feel free to give us a call and a representative will speak with you today!

Send Requests For Quote to Multiple Industrial Lasers Suppliers Near You

Provide your project details, and we'll connect you to 5-20 qualified industrial lasers companies in your region. 100% free.

Get InformationManually Sourcing U.S./Canadian Manufacturers for 20+ Years

More Laser Manufacturers

Lasers produce beams of monochromatic, coherent radiation (light) and are designed to concentrate high amounts of energy over a defined point. The term laser is an acronym for Light Amplification by Stimulated Emission of Radiation. This helps us understand that, through stimulated emission, lasers release a beam of electromagnetic radiation (beam of light).

Applications

Depending on the strength of the laser, there are many different applications for laser technology across the medical, manufacturing, construction, and electronics industries. Typical laser applications include cutting, welding, etching, engraving, heat treating metals and plastics, surveyors, pointing, and leveling. They can also be used as laser weaponry. Laser weapon systems are used by the US Navy to destroy, cripple, or warn targets. Laser beams from laser weapons can also be used by other military groups to shoot down missiles and drones.

The weakest lasers, such as laser modules, are used as laser pointers, leveling tools, and surveyors. Hospitals, dentist offices, and doctor offices use dental lasers and medical lasers for surgeries and optical procedures. The most high-power laser systems are used in material fabrication. These industrial lasers, suppliers of which are found on IQS Directory, are strong enough to carry out those applications of cutting, welding, etching, engraving, and heat treating metals and plastics.

The History of Lasers

Lasers trace their beginnings to Albert Einstein and his article released in 1917, “On the Quantum Theory of Radiation.” Via the discussion of emissions from proton travel and atoms in an excited state, he proposed the possibility of stimulated emission. Of course, his theory proved correct. Scientists did not begin exploring it, though, until the 1940s and 1950s.

Charles H. Townes, an American physicist, was one of the first to begin this work. During World War II, he had worked on radar systems. Once the war was finished, he pivoted to the study to a similar field, molecular spectroscopy. Using molecular spectroscopy, he could send light energy into groups of molecules, watch the radiation energy scatter them, and study their structure. This practice was useful but limited. Townes wished to use shorter microwave wavelengths, but he could not produce them with the technology on hand. His first idea was to make a device that used Einstein’s stimulated emission to produce light energy with shorter wavelengths. From that, in 1953, he produced the maser (Microwave Amplification by Stimulated Emission of Radiation). The maser worked similarly to the laser, but amplified microwave radiation instead of visible or infrared radiation.

In 1957, while working for Bell Labs, Townes began working on the laser. It was his colleague, Arthur Schawlow, who suggested he use mirrors to focus the light energy. This proved to be the catalyst for laser creation. Together, in 1958 Townes and Schawlow published a paper on their theory in the Physical Review. In 1960, they received a patent for their idea. Before they could build their laser, though, that same year, Theodore H. Maiman, working for Hughes Research Labs, built one first. He based his laser on the work of Townes and Schawlow. His laser radiation relied on a solid state, flashlamp-pumped synthetic ruby crystal. With it, it emitted a 694 nanometer wavelength, red light laser beam. This type of laser became known as a diode-pumped solid-state (dpss) laser. Unfortunately, his laser could only pulse its beam.

The 1960s was an important decade for the laser. During those years, scientists made many advances in laser technology. For example, also in 1960, Ali Javan, along with Donald Herriott and William R. Bennet, produced the first gas laser. Unlike Maiman’s laser, their laser could be used for continuous operation. It used neon and helium gas. In 1993, Javan was recognized for his work with the Albert Einstein Award. In 1962, Robert N. Hall built the first laser diode system. It emitted near-infrared bands of laser light. That same year, Nick Holonyak, Jr. built the first diode laser that emitted light in the visible spectrum.

Since those first bursts of productions, scientists and engineers have made countless improvements on laser technology. They have, for example, improved their max pulse power, max output power, efficiency, and output duration. They have also widened the wavelengths they emit, the materials they use and the uses of lasers. Today, laser products are so precise that they can even be used in DNA sequencing. Scientists continue to research and develop new possibilities with lasers. As time goes on, we can expect more and more innovations.

Design

Gain Medium Materials

Common gain medium materials include:

• Solid-state laser materials like: neodymium-yttrium aluminum garnet (ND: YAG)

• Inert and reactive gaseous state materials like: ionized gas (ion laser), helium, helium-neon, carbon dioxide (CO2), chlorine, fluorine, argon, krypton, and xenon

• Liquid materials like organic dyes

• Semiconductors

Considerations and Customization

When building a custom laser, suppliers can vary laser products greatly in terms of their size, output, beam quality, laser power consumption, pumping system, and operating life. If they are working with industrial fiber lasers, they can also coil or bend the fiber in order to change light beam quality or save space.

Suppliers make their choices based on application specifications like the material the laser will be impacting (skin, plastic, metal etc.), the type of application (burning, laser cutting, welding, pointing, etc.) required power, required sensitivity, required precision, available space, etc. Learn more about custom laser fabrication by talking to your potential suppliers.

Features

All lasers consist of an optical cavity, a gain medium, and a pumping system.

The optical cavity contains the media, which is the source of the laser light, and the mirrors that excite the media and direct the produced photons back along the same general path. (Photons are particles that carry energy and represent the laser light. Photons have zero rest mass.) The laser medium can be a solid, a gas (e.g. argon), liquid dye, or semiconductors, as is the case in diode lasers.

Pumping systems transfer energy to the media in three basic ways. In optical pumping, the system utilizes photons from another source, such as a xenon gas flash laser tube. Collision pumping transfers energy using an electrical discharge within the pure gas or gas mixture media. Pumping systems may also rely on the binding energy released in chemical reactions in order to raise the media to the lasing state.

Types

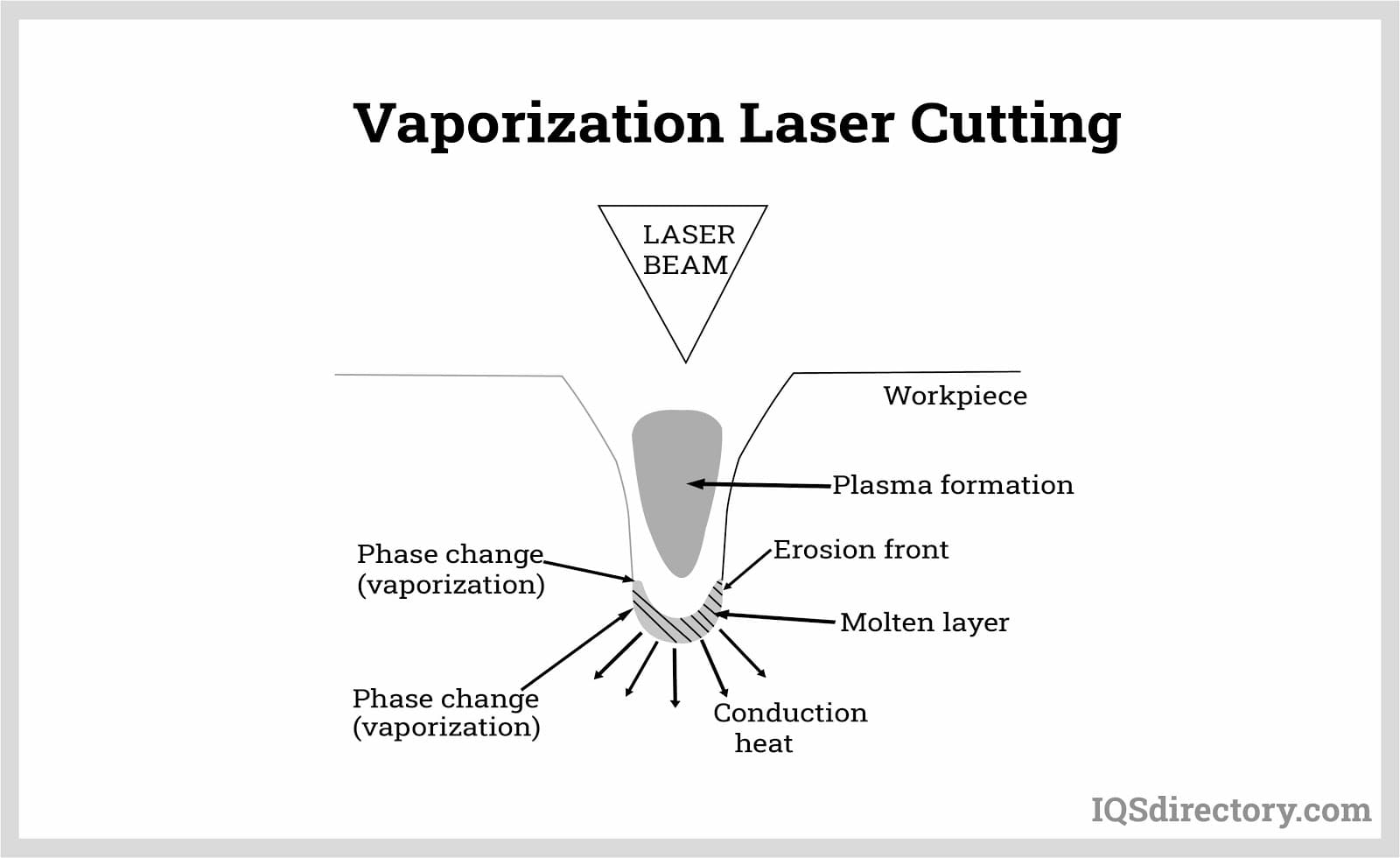

CO2 lasers use contained CO2 gas to produce their energy. CO2 lasers, which can run for thousands of hours before a new CO2 supply is needed, work very well with most metals, wood, plastics, ceramics, glass, and quartz. They are used for deep laser cutting and welding applications.

Diode lasers, also referred to as “semiconductor lasers,” utilize microscopic chips made of gallium-arsenide or another semiconductor to generate their source of coherent laser light. Diode lasers are usually smaller and less powerful than other lasers, as they are used for small, low power applications. Laser diodes can be found in CD-ROM drives, CD players, barcode scanners, and laser printers.

Dye lasers use complex organic dyes in a liquid solution or suspension as a lasing medium. Dye lasers have the ability to be tuned over a wide range of wavelengths.

Embedded lasers have a higher inherent capability than the laser system into which they are incorporated, where the lower assigned class number of the system is appropriate to the engineering features that limit accessible emission.

Excimer lasers produce short, intense ultraviolet (UV) light pulses and have the greatest power and versatility of any light source in the UV range of the electromagnetic spectrum. They are used only for laser cutting and burning operations. Also known as ultraviolet excimer lasers, excimer lasers are widely used in the scientific, industrial, and medical industries.

Fiber lasers are powerful solid-state laser systems used for laser cutting, marking, engraving, welding, annealing, sintering, drilling, printing, ablation, and scribing. They are useful in settings including telecommunications, optical communications, electronics, medical devices, healthcare, metalworking, plastic fabrication, automotive manufacturing, and material processing. They use optical fibers doped with small amounts of rare earth ions or halides, such as ytterbium, erbium, praseodymium, or neodymium.

Helium neon lasers are lasers that are generated through the electrification of helium and neon in an enclosure.

Industrial lasers are laser systems used in industrial settings for cutting, welding, singeing, etching, and other processes.

Internal mirror lasers are lasing devices constructed with the reflecting cavity mirror attached to the containment envelope that houses the gas.

Laser modules are small laser systems that are often portable, low power and used for more consumer applications than industrial or commercial applications. A few examples are laser pointers and laser levels.

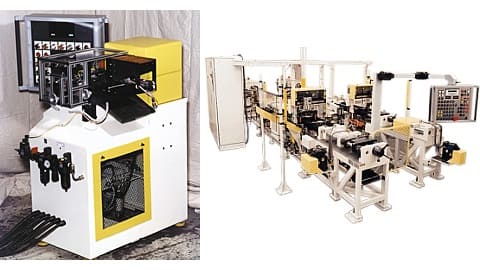

Laser systems are used for many applications, including metal, die board and plastic cutting, metal and non-metal marking, and micro-machining.

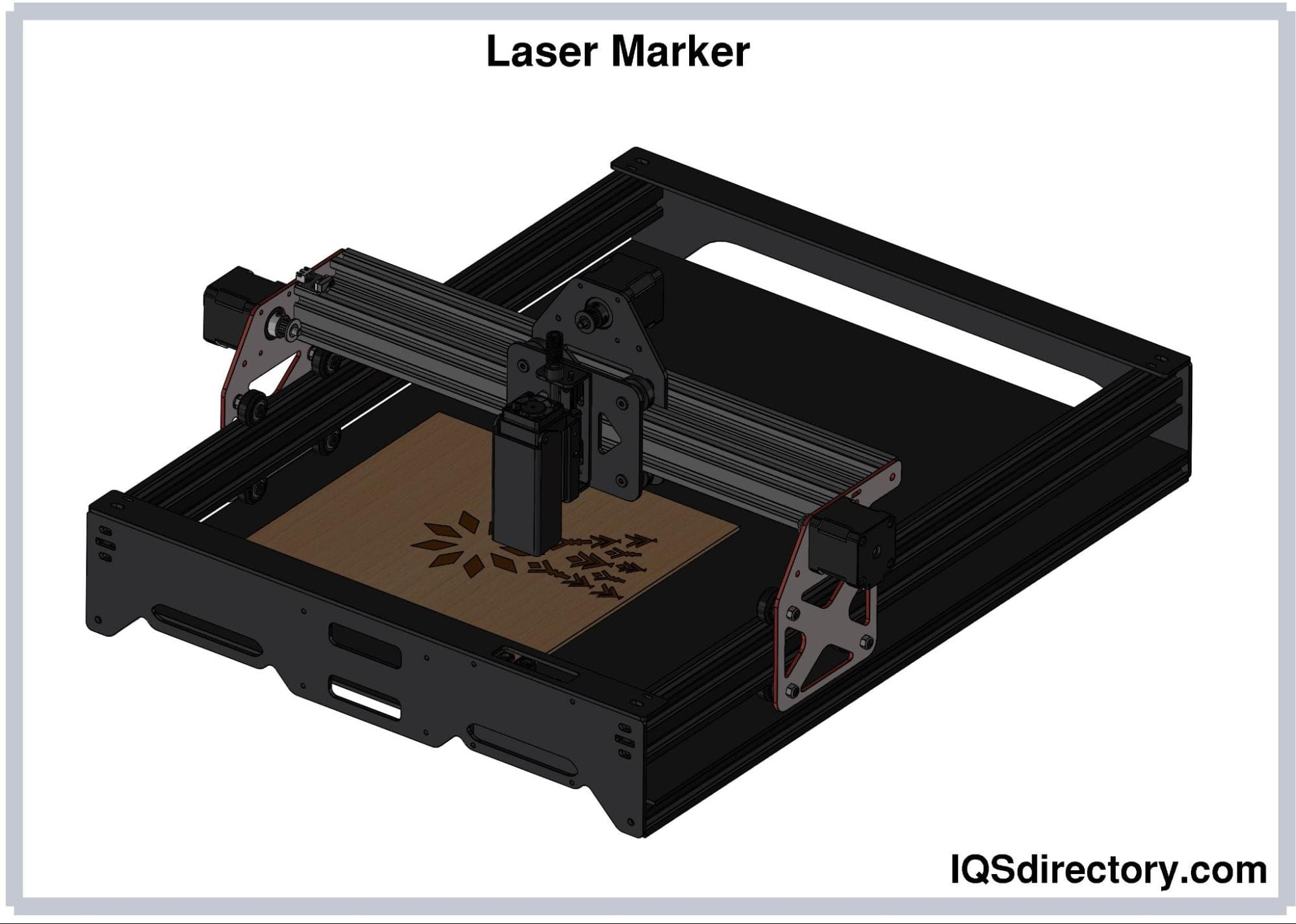

Marking lasers are used to scribe letters, words, designs, etc., on different materials, such as ceramics, wood, and glass. Different lenses provide variations in laser diameter, which in turn increases or decreases the thickness of the marking.

Medical lasers are used in lieu of scalpels and other medical instruments because of their precision.

Yttrium aluminum garnet lasers, also referred to as “Nd: YAG lasers” or “YAG lasers,” are solid state lasers that use neodymium-doped YAG crystals as the lasing mediums. YAG lasers are available in constant and pulsing configurations and are generally used for such applications as laser marking, cutting, deep cutting and welding.

Solid-state lasers (solid state lasers) are laser systems in which a laser beam is generated by the electrification of a solid gain medium. Gain media are the sources of light and the mechanism of light amplification in laser systems.

Visible lasers emit light with a wavelength in the visible spectrum, which may be red, green, violet, or blue. While most lasers are infrared and therefore invisible to the naked eye, many applications require visible light lasers.

Welding lasers present a quick exposure time with little material outside the focus area being heated. Welding lasers, which operate with a very dense energy, are extremely precise and can perform welds that a human welder cannot.

Advantages of Lasers

Lasers offer many advantages. First, they have a high stability output and will operate reliably over long-term periods, requiring minimal service. Second, laser manufacturers provide dependable solutions for high-duty cycle/continuous-use applications. Depending on the repetition rate, lasers can operate continuously for hundreds or even thousands of hours.

Accessories

Common laser equipment accessories include drivers, mounts, safety goggles, and other protective gear, cover detectors, laser projectors, optical isolators, optical system design software, crystals, choppers, rotary laser levels, and shutters.

Proper Care and Usage

When you purchase a laser, you need to be aware of its dangers and the safety precautions you need to take. That is because exposure to lasers can cause severe damage to people and property. To help guide you, all suppliers divide their lasers into 5 classes, according to their power output and laser hazards: Class I, Class II, Class IIIa, Class IIIb and Class IV. Laser manufacturers are required to build in engineering controls in laser systems to provide added safety measures.

Class I lasers are the weakest kind and pose zero biological hazard. Their power is less than 1mw, and they are mostly used as pointers.

Class II lasers are also safe to use, though they can damage eye tissue if focused there. They are powered up to 1mw.

Class IIIa lasers are a little more dangerous. At 1 to 5mw, eye injury is possible, but these products will not burn any materials.

Class IIIb lasers, powered up to between 5 and 500mw, will cause eye damage and may burn materials.

Class IV lasers are the most dangerous at 500mw or more. They burn any material on contact, including human skin and hard metals.

All lasers, no matter what their power, must have an enclosure around them that limits access to the light beam. Class IV systems contain the most dangerous laser lights and require a master switch that, when disabled, prohibits all but authorized personnel from operating the laser. All Class IV lasers must have a light beam stop or attenuator, which significantly reduces light beam emission when the laser is on standby, permanently attached to them. We also recommend this for Classes IIIa and IIIb.

Other safety precautions you may want to institute include access restriction to the lasing area, eye protection, area controls, barriers, shrouds, education, and training.

Standards

In addition to the right classes, you should make sure that any laser products you purchase have received certification from the right organizations for your application, industry, and location. For example, ANSI puts out laser safety guidelines for industries including the military, medical field, educational field, and industrial field. In addition, OSHA puts out standard requirements for working with lasers. It’s always important to make sure both your laser and your work environment meet OSHA requirements. The FDA has their own laser standards as well. To learn more about what standards your lasers should meet, talk to your industry leaders and applicable governmental offices.

Choosing the Right Manufacturer

Lasers are extremely sensitive devices even when they are made right and matched properly with an application. If they malfunction or they aren’t right for your application, they can be downright dangerous. That’s why it’s so important that you make sure to work with an experienced laser manufacturer that you trust. To help you find the right one, we’ve compiled a list of some of the best laser manufacturers in the business. You’ll find their information and profiles by scrolling up towards the top of this page. Take some time to peruse their products and services. Figure out which ones appear to offer the products and services that match your needs the best. Pick out three or four you’d like to speak with, then reach out to them. Discuss your specifications, including your budget, timeline, standard requirements, delivery preferences, and support preferences. Before speaking with them, you may want to write all your specifications down so that you’ll be prepared for the conversations. After speaking with each of them, compare and contrast their answers. Choose the right one for you and get started.

Automation Equipment

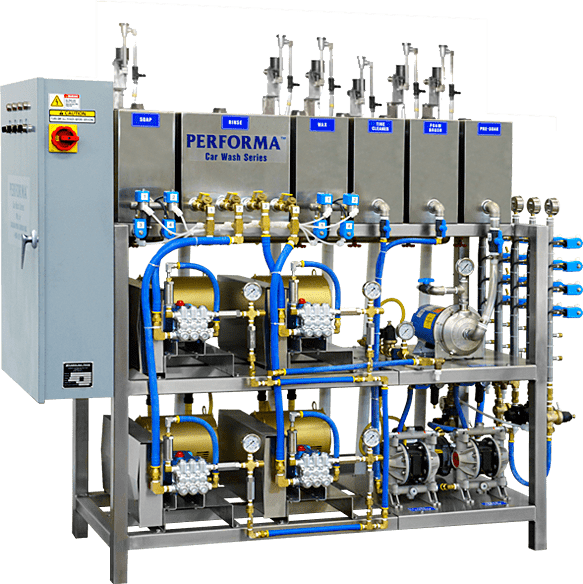

Automation Equipment Car Wash Equipment

Car Wash Equipment Centrifuges

Centrifuges Hydraulic Presses

Hydraulic Presses Lasers

Lasers Machinery Rebuilders

Machinery Rebuilders Paint Finishing Equipment

Paint Finishing Equipment Tube Forming Machines

Tube Forming Machines Castings & Forgings

Castings & Forgings Bulk Material Handling

Bulk Material Handling Electrical & Electronic Components

Electrical & Electronic Components Flow Instrumentation

Flow Instrumentation Hardware

Hardware Material Handling Equipment

Material Handling Equipment Metal Cutting Services

Metal Cutting Services Metal Forming Services

Metal Forming Services Metal Suppliers

Metal Suppliers Motion Control Products

Motion Control Products Plant & Facility Equipment

Plant & Facility Equipment Plant & Facility Supplies

Plant & Facility Supplies Plastic Molding Processes

Plastic Molding Processes Pumps & Valves

Pumps & Valves Recycling Equipment

Recycling Equipment Rubber Products & Services

Rubber Products & Services