Isotech offers a full range of Fiber, C02, UV, Green, MOPA, Nanosecond, Picosecond and Femtosecond laser systems for marking, cutting and welding of many substrates. Isotech offers both standard systems as well as fully automated or custom systems depending on your specific requirements. Integrated, automated solutions with conveyors, palletized pick and place, rotary dial tables, hoppers, and...

At Boss Laser, we are a leading provider of industrial-grade laser cutting and engraving machines for a wide range of applications. Our machines are built with precision, durability, and efficiency in mind, designed to provide our customers with the most advanced technology available in the market.

At LNA Laser Technology, we specialize in delivering advanced laser solutions tailored to meet the evolving needs of modern manufacturing and precision processing. As pioneers in laser integration, we combine engineering expertise with a deep understanding of laser systems to develop customized applications that enhance productivity, accuracy, and operational efficiency.

Laser Marking Technologies LLC engineers laser systems for the medical, manufacturing, and automotive industries. We provide you cutting-edge technology at competitive prices. We are making innovative strides with fiber lasers, 3D printing tech, and automation capabilities that optimize manufacturing processes. Visit our site today to learn more about what our laser expertise can do for you.

At Tecnar Automation, we specialize in developing advanced laser-based technologies that empower manufacturers to achieve greater precision, control, and efficiency in their production processes. Since our founding, we’ve dedicated ourselves to pushing the boundaries of industrial measurement and inspection through robust, real-time solutions designed for the most demanding environments.

If your business has a challenging component to mark on, our team at Automark will help you solve the problem. We supply laser and marking systems for a multitude of industries. Our team of engineers is ready and willing to tackle any of your challenging assignments. If you have any questions feel free to give us a call and a representative will speak with you today!

More CO2 Laser Manufacturers

CO2 Lasers in Industrial Metalworking: Applications, Benefits, and Buying Guide

Lasers, especially a laser as common as the CO2 laser, are valued as essential metalworking machines due to their unique advantages over traditional metal fabrication methods. Across industries ranging from electronics, automotive, and aerospace to medical device manufacturing, industrial laser cutting systems have become indispensable for achieving precision, speed, and cost-effectiveness. This comprehensive guide explores the science behind CO2 lasers, their diverse applications, key benefits, and critical purchasing considerations—empowering both buyers and researchers to make informed decisions when selecting the ideal CO2 laser system for their specific needs.

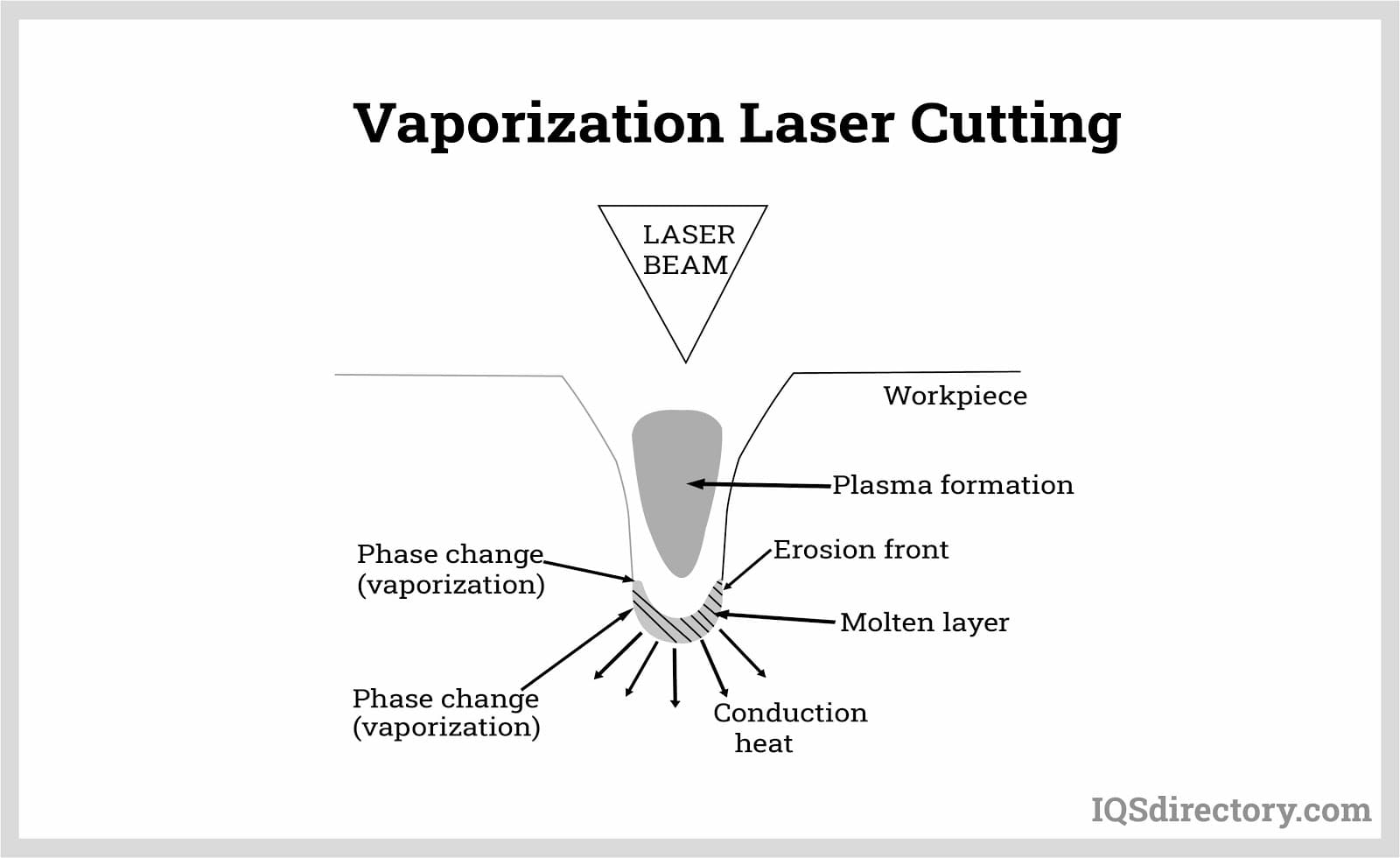

What is a CO2 Laser? Understanding the Technology Behind Laser Cutting

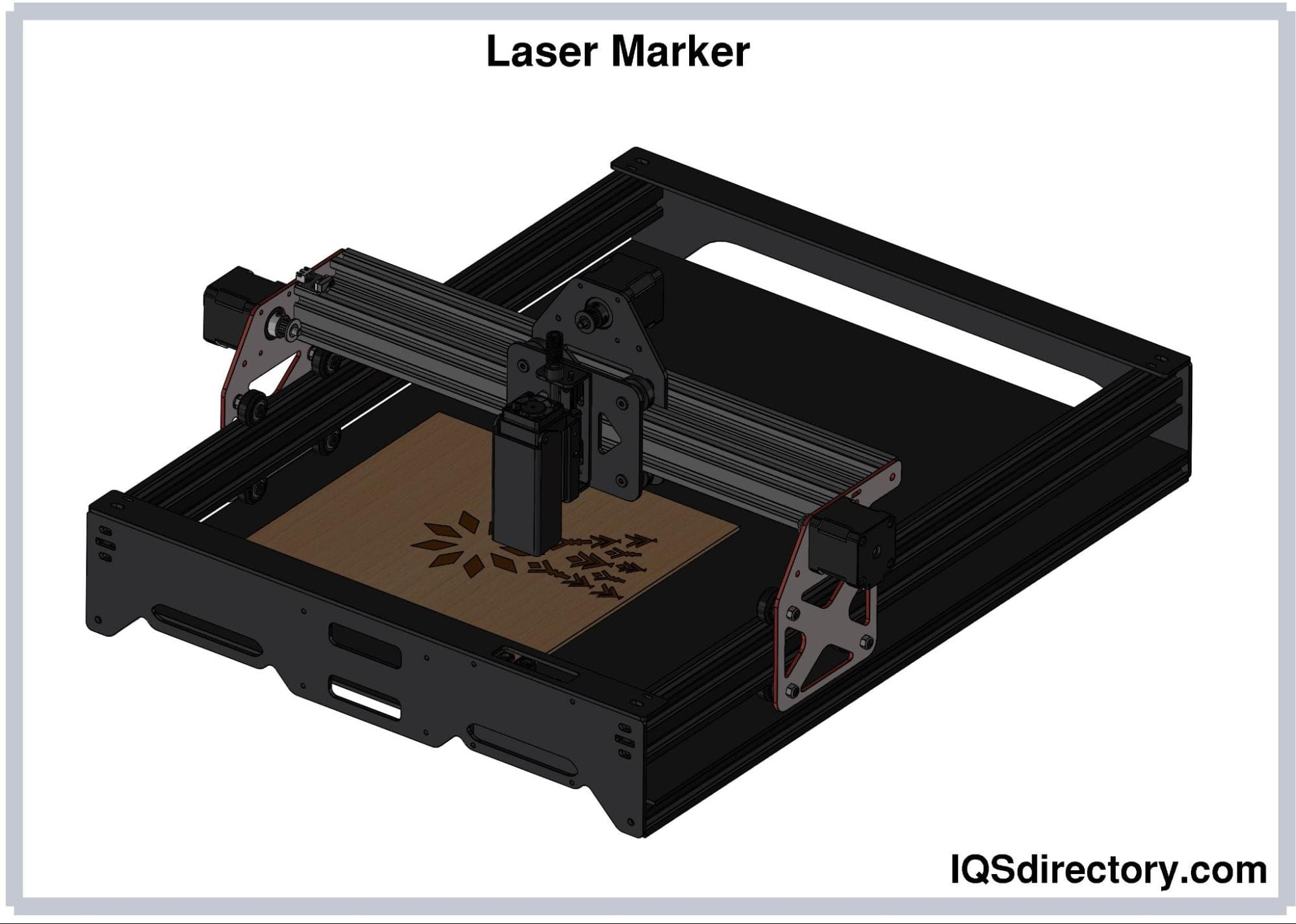

Laser is an acronym for Light Amplification by Stimulated Emission of Radiation. In essence, a laser system is a highly specialized device that generates, amplifies, and focuses an intense beam of light. This focused light, when directed at a target material, produces a precise, controlled heat source capable of altering, engraving, or cutting the material without physical contact.

CO2 lasers are a specific type of gas laser that uses a mixture of carbon dioxide, nitrogen, and helium as the gain medium inside the optical amplification cavity. When stimulated by an electric current, the gas mixture emits photons, creating a powerful infrared laser beam (typically at a wavelength of 10.6 microns). This beam is then directed by mirrors and focused through lenses to create pinpoint heat at the desired location on the workpiece.

Key Components of a CO2 Laser System:

- Optical Amplification Chamber: Filled with CO2 gas and other additives to boost laser efficiency.

- Power Supply: Provides the necessary electrical energy to excite the gas molecules.

- Mirrors & Lenses: Direct and focus the laser beam with extreme accuracy.

- Control System: Enables computer numerical control (CNC) for automated, programmable cutting and engraving.

Why Choose CO2 Lasers for Metalworking?

CO2 lasers are prized in industrial and manufacturing environments for several reasons:

- Non-Contact, Precision Processing: Unlike mechanical tools such as saws, blades, or stamping presses, laser cutting is a non-contact process. This eliminates tool wear, reduces maintenance costs, and prevents physical deformation or surface damage to the workpiece.

- Minimal Heat-Affected Zone (HAZ): The focused nature of the CO2 laser beam ensures that heat is confined to a very small area, which helps maintain the mechanical integrity, flatness, and surface quality of the material being processed.

- High-Speed, Automated Production: Modern CO2 laser cutters integrate seamlessly with CNC machinery, enabling rapid, repeatable, and highly accurate fabrication—even on intricate geometries or thin materials.

- Clean Cuts, No Contaminants: Because there are no moving blades or abrasive contacts, CO2 lasers cut metals without leaving microscopic blade shards, burrs, or other contaminants. This is especially critical in industries where material purity is non-negotiable, such as semiconductor manufacturing or medical device production.

- Versatility Across Materials: In addition to metals, CO2 lasers can process a wide range of non-metallic materials, including plastics, glass, ceramics, wood, textiles, and composites—making them highly adaptable for multi-material production lines.

Core Applications of CO2 Lasers in Industry

CO2 lasers are widely used in a broad array of industrial applications where precision, speed, and quality are paramount. Common use cases include:

- Laser Cutting: Clean, burr-free cutting of sheet metal, stainless steel, aluminum, titanium, and other metals for industrial fabrication, enclosure manufacturing, and custom component production.

- Laser Engraving & Marking: Permanent, high-resolution labeling of small electronic parts, circuit boards, medical instruments, and identification tags—without damaging delicate surfaces.

- Laser Welding: Joining thin metal sheets, wires, or components with minimal distortion, ideal for fine mechanical assemblies and electronics.

- Micro-Machining: Creating micro-scale holes, channels, or features in metals, ceramics, and polymers for research, sensor manufacturing, and medical devices.

- Surface Treatment: Texturing, cleaning, or patterning metal surfaces to enhance adhesion, improve aesthetics, or prepare for coating processes.

- Medical & Dental Procedures: CO2 lasers are used for precision skin resurfacing, dental surgery, and tissue ablation due to their gentle, controllable energy delivery.

- Prototyping & Customization: Rapid production of prototypes, custom signage, artwork, and architectural models in a variety of materials.

What industries benefit most from CO2 laser systems?

CO2 laser technology is a cornerstone in sectors such as:

- Automotive Manufacturing: Cutting and welding of car body panels, exhaust components, and intricate dashboard electronics.

- Aerospace & Defense: Precision fabrication of aircraft parts, turbine blades, and flight control systems.

- Electronics Production: Marking and engraving of microchips, sensors, and connector housings.

- Medical Device Manufacturing: Etching of surgical tools, implants, and instruments requiring absolute cleanliness.

- Jewelry & Watchmaking: Intricate engraving, filigree, and micro-welding for luxury goods.

- Packaging & Labeling: High-speed engraving and marking of product packaging, barcodes, and serial numbers.

Comparing CO2 Lasers to Other Laser Types

Understanding the differences between CO2 lasers and other popular industrial laser technologies—such as fiber lasers and Nd:YAG lasers—is crucial for selecting the right machine for your application. Here’s a quick comparison:

| Laser Type | Wavelength | Best For | Advantages | Limitations |

|---|---|---|---|---|

| CO2 Laser | 10.6 μm | Non-reflective metals, plastics, wood, glass, ceramics | Versatile, clean cuts, good for organic materials | Lower efficiency on reflective metals (e.g., copper, brass) |

| Fiber Laser | 1.06 μm | Ferrous & non-ferrous metals, high-volume cutting | Higher speed, lower maintenance, great for thin metals | More expensive, less effective on some non-metals |

| Nd:YAG Laser | 1.064 μm | Marking, engraving, some metal cutting | High peak power, fine detail, pulsed operation | More complex maintenance, shorter lifespan |

Advantages of Using CO2 Laser Cutting Systems

Whether you’re investing in your first industrial laser or upgrading an existing fabrication line, CO2 laser machines offer compelling benefits:

- Exceptional Precision: CO2 lasers allow for micron-level resolution in cutting and engraving, making them ideal for fine features and detailed custom work.

- Reduced Waste and Rework: The accuracy and repeatability of laser processing minimize material waste, costly errors, and the need for secondary finishing operations.

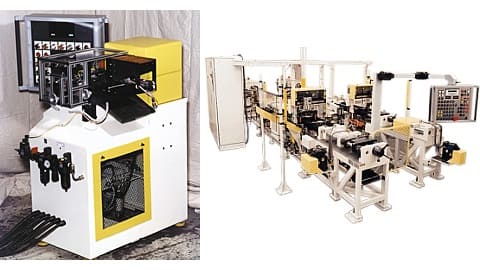

- Automation and Integration: Modern CO2 laser systems can be seamlessly integrated into smart factories, with advanced CNC control, IoT monitoring, and robotic handling for lights-out manufacturing.

- Lower Operating Costs: Compared to consumable-intensive processes (e.g., waterjet, plasma), CO2 lasers have fewer wear parts and require less ongoing maintenance.

- Safe, Clean Work Environment: Laser systems generate minimal noise, dust, and hazardous byproducts, supporting a safer and cleaner production facility.

- Broad Material Compatibility: Cut, engrave, and mark a diverse range of metals and non-metals with a single machine, maximizing ROI.

Key Considerations When Choosing a CO2 Laser Cutter

When researching or purchasing a CO2 laser cutting machine, several factors directly impact performance, versatility, and long-term value:

- Laser Power Output: Higher wattages (e.g., 100W–600W) enable thicker metal cutting and faster processing. Match power to your typical material type and thickness.

- Work Area Size: Ensure the bed dimensions accommodate your largest workpieces or production runs.

- Cutting Speed & Resolution: Look for systems offering high linear speeds and fine positional accuracy for intricate jobs.

- Software & CNC Compatibility: Advanced software enables automated nesting, barcode reading, and integration with CAD/CAM systems for streamlined workflow.

- Maintenance & Service: Consider the availability of local support, ease of optics replacement, and system reliability.

- Safety Features: Look for interlocks, enclosed workspaces, and fume extraction to protect operators.

- Budget & ROI: Analyze total cost of ownership, including purchase price, energy consumption, consumables, and potential productivity gains.

CO2 Laser Engraving: Marking Small Electronic Parts and More

One of the most valuable uses of CO2 laser technology is in laser engraving and laser marking—especially on small, delicate electronic components where traditional marking methods fall short. Because laser engraving is a non-contact process, it avoids the risk of damaging sensitive surfaces, causing stress fractures, or introducing micro-contaminants. CO2 lasers can produce engravings as shallow as a few micrometers, ensuring even the smallest parts can be labeled with crisp, permanent, and readable identifiers.

Common laser engraving applications include:

- Micro-marking of resistors, capacitors, and microchips in electronics manufacturing

- Etching serial numbers, barcodes, and QR codes for traceability and anti-counterfeiting

- Personalizing medical instruments and surgical tools with UDI (Unique Device Identification) codes

- Branding luxury goods, jewelry, and watches for authenticity and aesthetics

What are the advantages of CO2 laser engraving over mechanical or ink-based marking?

- Durability: Laser markings are permanent, fade-resistant, and can withstand harsh environments.

- Cleanliness: No ink, chemicals, or physical force—ideal for sterile or contamination-sensitive industries.

- Speed and Flexibility: Change markings on the fly via software, enabling rapid prototyping and small-batch customization.

- No Tool Wear: Maintains consistent quality with zero risk of dull or damaged marking tools.

Frequently Asked Questions About CO2 Lasers

What materials can a CO2 laser cut?

CO2 lasers excel at cutting a wide array of materials including mild steel, stainless steel, aluminum, titanium, plastics (acrylic, polycarbonate), wood, leather, glass, ceramics, paper, and more. They are especially effective on non-metallic and organic materials where fiber lasers may struggle.

How thick can a CO2 laser cut?

The maximum cutting thickness depends on the laser’s power rating. For example, a 150W CO2 laser can typically cut up to 6–8mm of mild steel, while high-power models (400W+) can process metals up to 20mm or more. Always consult the manufacturer’s specifications for precise capabilities.

Is a CO2 laser safe to operate?

Modern CO2 laser machines are engineered with comprehensive safety features, including interlocks, emergency stops, and fume extraction systems. Operators should always follow manufacturer guidelines and wear appropriate eye protection.

What is the expected lifespan of a CO2 laser tube?

CO2 laser tubes typically last 2,000–10,000 hours depending on usage, cooling, and maintenance. Regular cleaning and timely replacement of optics will extend the operational life of your system.

How does laser cutting compare to waterjet or plasma cutting?

Laser cutting offers unmatched precision, lower operating costs, cleaner edges, and greater automation potential compared to waterjet and plasma technologies. However, waterjet excels at cutting thick or reflective materials, while plasma is ideal for fast, rough cuts in thick metals.

CO2 Laser Maintenance and Troubleshooting Tips

Proper maintenance is key to maximizing the lifespan, performance, and safety of your CO2 laser cutter. Here are best practices for keeping your system in top condition:

- Clean Optics Regularly: Dust and residue on mirrors or lenses degrade beam quality and cutting performance. Use manufacturer-approved cleaning kits and follow recommended intervals.

- Inspect Cooling Systems: Ensure water or air cooling systems are functioning correctly to prevent overheating and extend laser tube life.

- Monitor Gas Levels: For sealed CO2 lasers, check for leaks and maintain optimal gas composition as specified.

- Check Alignment: Periodically verify that mirrors and lenses are correctly aligned for maximum beam efficiency.

- Update Software: Keep control software and firmware up-to-date to benefit from performance improvements and bug fixes.

- Follow a Preventive Maintenance Schedule: Document maintenance activities and adhere to the manufacturer’s service intervals to avoid unexpected downtime.

Conclusion: Unlocking Productivity and Precision with CO2 Laser Technology

CO2 lasers have revolutionized modern manufacturing, offering unmatched versatility, precision, and efficiency across countless industrial applications. Whether you require high-speed metal cutting, detailed engraving for electronics, or adaptable processing for diverse materials, CO2 laser cutting systems deliver a compelling blend of performance and value. By understanding the science, applications, and decision factors outlined in this guide, you can confidently choose the right laser machine to elevate your workflow and achieve superior results.

Ready to take the next step? Contact our laser engineering experts for tailored recommendations, product demos, or a custom quote—and discover why leading manufacturers trust CO2 lasers to power their success.

Automation Equipment

Automation Equipment Car Wash Equipment

Car Wash Equipment Centrifuges

Centrifuges Hydraulic Presses

Hydraulic Presses Lasers

Lasers Machinery Rebuilders

Machinery Rebuilders Paint Finishing Equipment

Paint Finishing Equipment Tube Forming Machines

Tube Forming Machines Castings & Forgings

Castings & Forgings Bulk Material Handling

Bulk Material Handling Electrical & Electronic Components

Electrical & Electronic Components Flow Instrumentation

Flow Instrumentation Hardware

Hardware Material Handling Equipment

Material Handling Equipment Metal Cutting Services

Metal Cutting Services Metal Forming Services

Metal Forming Services Metal Suppliers

Metal Suppliers Motion Control Products

Motion Control Products Plant & Facility Equipment

Plant & Facility Equipment Plant & Facility Supplies

Plant & Facility Supplies Plastic Molding Processes

Plastic Molding Processes Pumps & Valves

Pumps & Valves Recycling Equipment

Recycling Equipment Rubber Products & Services

Rubber Products & Services